Asphalt plant BMZ-80

1 299 351 THE VILLAGE

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

171 502 THE VILLAGE

- Twin-shaft asphalt mixer BMZ-80-01

- Twin-shaft asphalt mixer BMZ-80-01

- Twin-shaft asphalt mixer BMZ-80-01

- Twin-shaft asphalt mixer BMZ-80-01

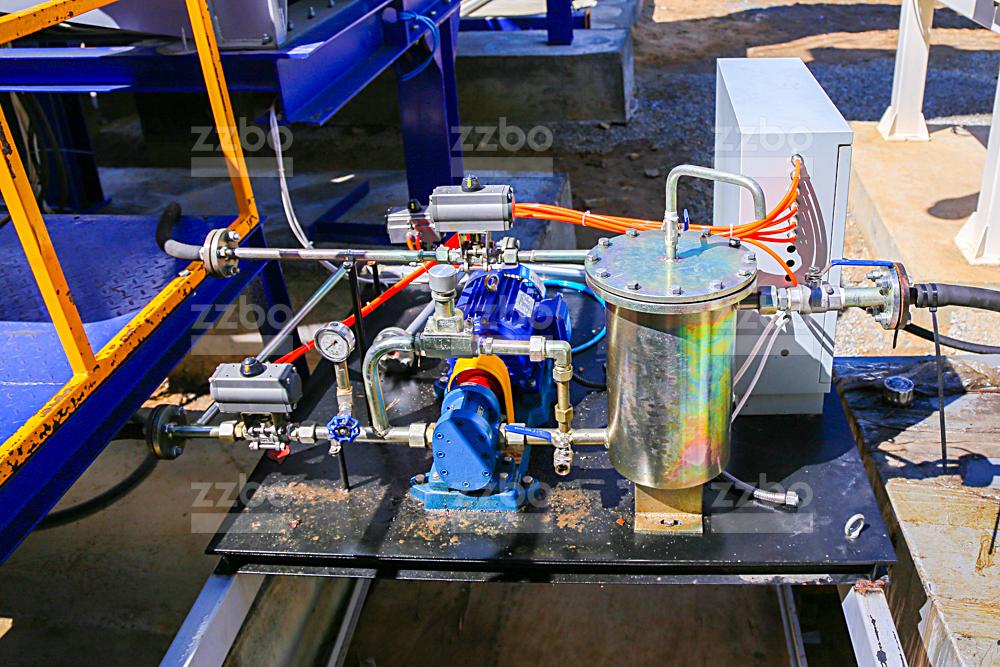

- Pneumatic valves

- Connection set for pneumatic equipment

- Electricity to connect the remote control

- Operational documentation

166 338 THE VILLAGE

- Software on your own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work in the local network

- Programmable Logic Controller

- Control panel/power cabinet in a dust and waterproof IP54 housing

- Control, protective and switching equipment "Siemens" (substitutes with similar characteristics are possible)

- Set of diagrams and instruction manual

85 978 THE VILLAGE

- Bunker of hot inert materials - 5 sections. The total volume is 14 cubic meters. meters

- Mounting frame

- Sector valves, with control of pneumatic cylinders – 5 pcs.

- Pneumatic equipment – 5 pneumatic distributors, a set of fittings and tubes

- Connection set for pneumatic equipment

- The sensors of the upper and lower layer

- Temperature sensor in the hopper for fraction 0 ... 4 mm

- Electricity to connect the remote control

- Operational documentation

75 120 THE VILLAGE

- Rumble - Dec 5 The total sieving area is 14 sq. meters

- Vibrators

- Screen replacement doors

- Spring support hatches

- Dust extraction

- Corrugated sieves made of spring steel

- Operational documentation

127 551 THE VILLAGE

- Drive power 11 kW

- 70 buckets with a volume of 8 dm33 each

- Buckets with reinforced outer edges

- Increased serviceability chain

- loading box

- Spring tension

- Bearing units of increased strength

- Drive maintenance platform

- Dust extractor

- Discharge neck

184 969 THE VILLAGE

- Cylindrical body with blades

- Base frame with driven rollers

- Box for receiving inert materials

- Flue gas removal

- Warming

- Electricity to connect the remote control

- Operational documentation

184 142 THE VILLAGE

- Five batchers of inert materials DIK-8

- Five batchers of inert materials DIK-8

- Five batchers of inert materials DIK-8

- Electricity to connect the remote control

- Operational documentation

40 618 THE VILLAGE

- Frame base

- snail body

- 55 kW drive

- Guide vanes with shutters

- damper swing actuator

- Vybrooporы

- Electricity to connect the remote control

- Operational documentation

86 782 THE VILLAGE

- Simplified operation due to the fact that the mixing unit can be removed without having to remove the burner from the boiler.

- Minimum and maximum flow adjustment for the first and second stages by means of an electric servomotor with a damper closing delay to prevent heat dissipation into the chimney.

- Equipped with one flange, one insulating jumper for fixing the boiler.

- Equipped with one flange, one insulating jumper for fixing the boiler.

52 551 THE VILLAGE

- Cyclone block

- Bunker dust collectors

- OLI MVE-300/3 Vibrator - 1 piece

- Butterfly valve

- Connection set for pneumatic equipment

- Electricity to connect the remote control

- Operational documentation

57 289 THE VILLAGE

- Drip eliminator on stand

- Chimney

- Service platform

- Water supply piping kit

- Pump "Calpeda NM 40 A / C" (Italy)

- Set of valves and pressure gauges

- Water tank for pump filling

- Venturi Duct Kit

- Electricity to connect the remote control

- Operational documentation

37 778 THE VILLAGE

- Operator's cab (insulated)

- Support frame (trestle)

- Platform with stairs

- Table

- Operational documentation

- Air conditioning

20 369 THE VILLAGE

- Hardware for assembling asphalt concrete: a dosing complex, a drying drum, a bucket elevator, a mixing tower, an operator's cabin, a cyclone and a wet dust collector, a fan

- Hardware, accessories

- Kit for installing nodes on the foundation (anchor bolts, clamping strips)

- Kit for fixing augers, chimney (rope, lanyards, clamps)

- Kit for sealing the joints of nodes (tarpaulins, hoses, sleeves, clamps, heat-resistant and universal sealants)

- Set for the water supply system (pipes, bends, couplings, sleeves, clamps)

- Set for the ABZ pneumatic system (pneumatic tubes, fittings, hardware, distributors, PPRS pipes and fittings, limit switch blocks)

- Set of wires for connecting ABZ

- A set of power and control cables protected by a metal hose and laid in trays

- Set of sensors (blocking, position, level, temperature, pressure)

- Mixing tower support kit

- Set of equipment for installation of cable networks

- Duct kit

28 636 THE VILLAGE

- Bunker with a volume of 8 cubic meters. meters

- Mounting frame

- Removable boards

- Conveyor feeder

- Oversized grille

- OLI MVE-300/3 Vibrator - 1 piece

- Electricity to connect the remote control

- Operational documentation

40 782 THE VILLAGE

- Truss conveyor on racks

- Roller bearings

- Guide rollers

- Pressure rollers

- Telescopic poles with stops

- The tape is smooth

- Scraper on driven drum

- Electricity to connect the remote control

- Operational documentation

148 151 THE VILLAGE

- Thermal oil boiler KTM-0.3

- Automatic control cabinet

- Pump LQRY-65-50-180/2-С, 5.5 kW (coolant temperature up to +300 °С)

- Chimney Du-250, deflector-spark arrestor

- Weather canopy

- Horizontal tank, nominal volume: V=28 m3, wall thickness S=6mm

- Execution material: steel 09G2S

- Register system - 2 pcs. Made from ⌀57 mm seamless pipe

- Thermal insulation of the tank (URSA basalt S=50 mm, lining - corrugated sheet S=0.5 mm)

- thermometer showing

- Service platforms with stairs - 1 pc.

- ARIES DTS thermal converter

- Ventilation system: deflector 250 mm, service hatch 600 mm

- System of pipes, flanges and bends

- Passport for autonomous bitumen storage

50 853 THE VILLAGE

- Bituminous foundry with a boiler on the frame — 1 pc.

- Block electric heater TENB-6Z, 6 kW — 20 pcs.

- Expansion tank of open type 50 liters - 1 pc.

- Automatic control cabinet — 1 pc.

- Hot oil pump - 1 pc.

- Flange 1-80-16 Steel 20 GOST 12820-80 (reciprocal) — 1 pc.

- Gasket A-80-16-PON GOST 15180-86 — 1 pc.

- Axial indicating thermometer BT-51.211 — 1 pc.

210 458 THE VILLAGE

- Two-block ready mix tank

- Skip distributor

- Two sections of the finished mixture, one section of the marriage (substandard)

- Pneumatic valves

- Connection set for pneumatic equipment

- Electricity to connect the remote control

- Operational documentation

59 138 THE VILLAGE

- Boiler on a frame with piping - 1 pc.

- Counter flanges Du-50 - 2 pcs.

- Automatic boiler control cabinet - 1 pc.

- Pump Calpeda NM4 50/25A/B-EYXYKRY FPM for hot oil +200 °C - 1 pc.

- Chimney Du-250, deflector-spark arrestor - 1 pc.

- Canopy against precipitation - 1 pc.

48 036 THE VILLAGE

- The tank is horizontal, nominal volume: V=31 m3, wall thickness S=6mm

- Execution material: steel 09G2S

- Register system - 2 pcs. Made from ⌀57 mm seamless pipe

- Thermal insulation of the tank (URSA basalt S=100 mm, sheathing - profiled sheet S=0.5 mm)

- thermometer showing

- Service platforms with stairs - 1 pc.

- ARIES DTS thermal converter

- Ventilation system: deflector 250 mm, service hatch 600 mm

- System of pipes, flanges and bends

- Passport for bitumen tank

116 356 THE VILLAGE

- Five batchers of inert materials DIK-8

- Fuel/combustion air flow control by means of two servomotors controlled by an electronic unit.

- Adjustment of the minimum and maximum air flow through an electric stepper actuator with damper closing during a pause so that heat does not dissipate in the chimney.

- Diesel Injector Cooling Secondary Air Adjustment Device

220 858 THE VILLAGE

- Equipped with one flange, one insulating jumper for fixing the boiler.

- Bunker of marriage (substandard)

- Bunker of marriage (substandard)

- Skip

- Bunker of marriage (substandard)

- Pneumatic valves

- Connection set for pneumatic equipment

- Electricity to connect the remote control

- Operational documentation

39 133 THE VILLAGE

- Bituminous plant assembled — 1 pc.

- Flanged full bore ball valve DN50 — 2 pcs.

- Flange 1-80-16 Steel 20 GOST 12820-80 (reciprocal) — 1 pc.

- Flange 1-50-16 Steel 20 GOST 12820-80 (reciprocal) - 2 pcs.

- Gasket A-50-16-PON GOST 15180-86 - 13 pcs.

- Gasket A-80-16-PON GOST 15180-86 — 1 pc.

- Термометр показывающий осевой БТ-51.211 (0-200)G-1/2".300.1,5 — 2 шт..

- Ladder — 1 pc.

- End fencing — 2 pcs.

- Large fence - 1 pc.

211 836 THE VILLAGE

- Top unit with filter bags and cleaning mechanisms

- Bottom unit of dust collecting bins with auger

- coasters

- Covers with manholes for maintenance

- Butterfly valves

- Connection set for pneumatic equipment

- Electricity to connect the remote control

- Operational documentation

20 533 THE VILLAGE

- RMK-2M unpacker with lid

- OLI MVE-300/3 Vibrator - 1 piece

- Butterfly valve

- Dispenser of cellulose additive MZ-020

- [object Window]

- Connection set for pneumatic equipment

- Electricity to connect the remote control

- Operational documentation

42 596 THE VILLAGE

- Silo tank (V = 35m3)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel based on polyurethane-acrylic resin produced by PentriMAX in the ATIS spray booth

- Machinery certificate

29 084 THE VILLAGE

- Silo Tank (V = 22m3)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Machinery certificate

82 053 THE VILLAGE

- The tank is horizontal, nominal volume: V=50 m3, wall thickness S=6mm

- Execution material: steel 09G2S

- Register system - 2 pcs. Made from ⌀57 mm seamless pipe

- Thermal insulation of the tank (URSA basalt S=100 mm, sheathing - profiled sheet S=0.5 mm)

- Reinforced support structures - 3 pcs

- Service platforms with stairs - 1 pc.

- ARIES DTS thermal converter

- Ventilation system: deflector 250 mm, service hatch 600 mm

- System of pipes, flanges and bends

- Passport for bitumen tank

81 827 THE VILLAGE

- Boiler on a frame with piping - 1 pc.

- Counter flanges Du-50 - 2 pcs.

- Automatic boiler control cabinet - 1 pc.

- Pump Calpeda NM4 50/25A/B-EYXYKRY FPM for hot oil +200 °C - 1 pc.

- Chimney Du-250, deflector-spark arrestor - 1 pc.

- Canopy against precipitation - 1 pc.

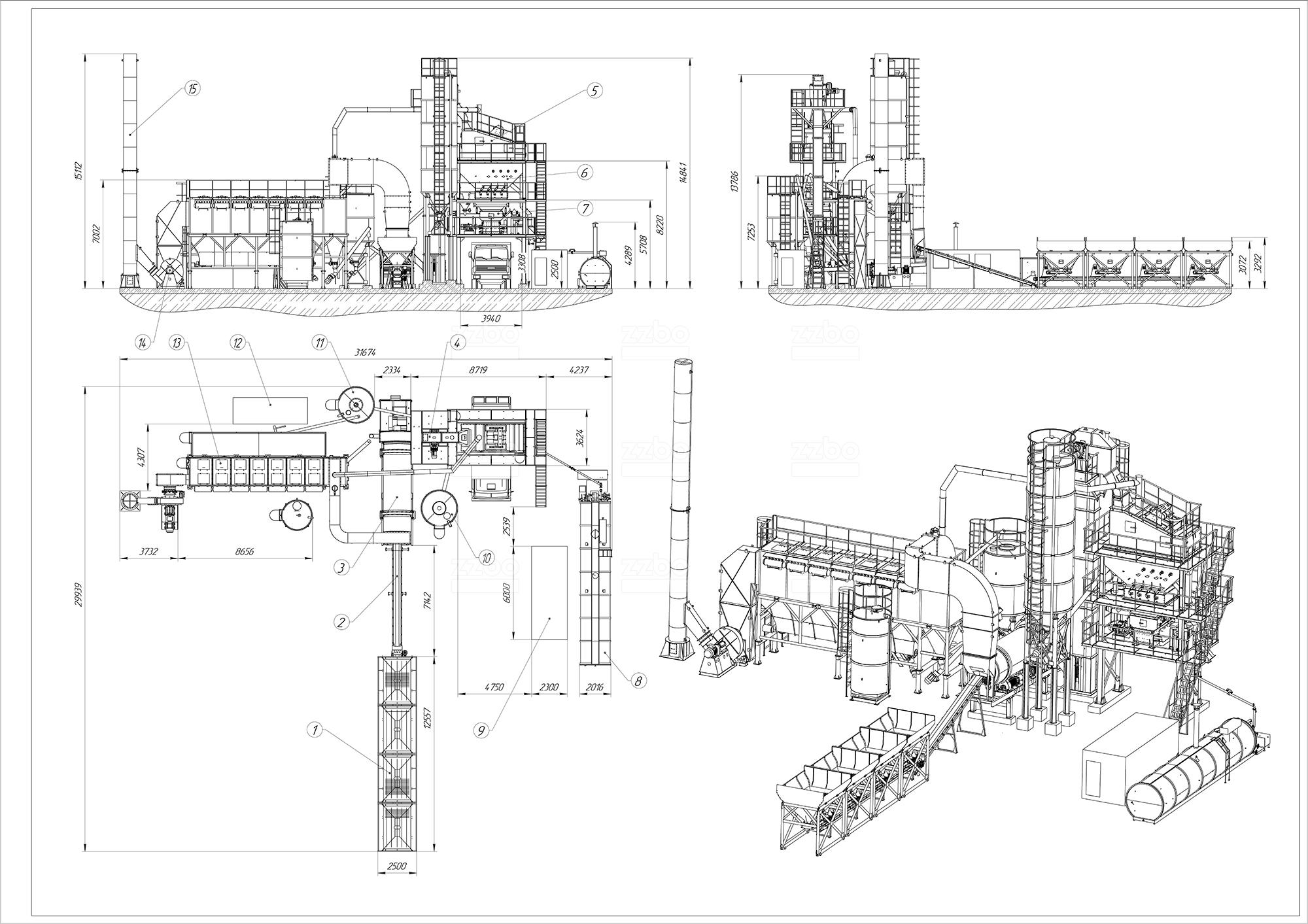

Asphalt plant model BMP-80, capacity of 80 tons of finished asphalt per hour.

Comes in different models, the selection of the necessary equipment assists the Sales Manager.

Job Description BMP-80

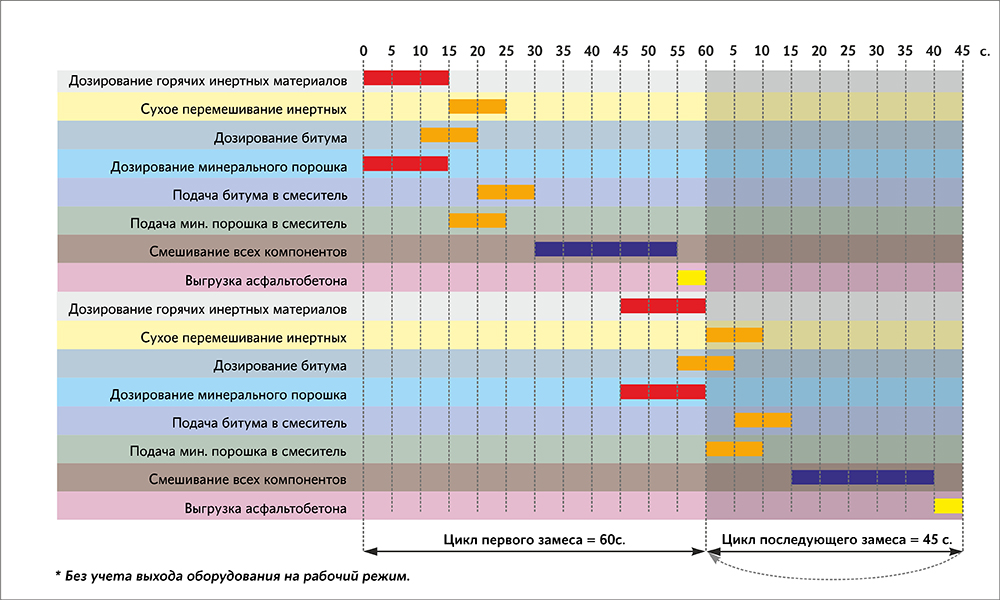

When loading dosing hoppers with inert materials (crushed stone and sand), they enter the drying drum in certain proportions, where they are dried and heated to 160 ° C by means of heating from the burner. The resulting dust and exhaust gases through the air duct system enter the filter unit, where the dust is separated and the exhaust gases are filtered. The separated dust is dosed and used to produce asphalt concrete.

After heating for elevator inert materials coming in bolt. The screen, in turn, separates materials into fractions and separates oversized inert materials, which are subsequently disposed of. The hot materials separated by fractions enter the storage bins of hot inert materials. Each of their fractions is weighed on a weight dispenser and in certain proportions (set based on the asphalt concrete formulation) enter the mixing drum.

In front of the mixing drum, mineral powder and bitumen dispensers are also installed. Mineral powder from the silo is fed into the batcher, weighed and sent to the dryer drum. In the same weigher, dust is weighed, which is filtered in the filter unit and used as it accumulates in the dust silo.

The bitumen is heated up to 150 °C in the bitumen storage, it enters the dispenser through the heated line, is weighed and pumped into the mixer. Initially, dry materials (crushed stone, sand, mineral powder) are mixed in the mixer, after bitumen is supplied, the final mixing takes place, which lasts no more than 20 seconds.

Ready asphalt comes from the mixing drum directly into the body of the truck.

- ZZBO production (Russia, Zlatoust). Warranty - 2 years

- Productivity - 80 tons per hour

- Service, spare parts and service from Russian manufacturer

- Automatic plant control SCADA-system, all data and control from one monitor

- All nodes in the transport envelope and delivery to the place of work of a typical transport

- A wide range of options: ext. silo, bitumen tanks, silos for powder and waste, all types of filters

Technical Features

- plant performance 80 t / h (3% moisture material)

- Supply hopper with inert materials, count and volume. 5 bins of 8 m3

- The thermal power of the burner 6500 kW

- Number screening sieves 5

- The volume of hot material hopper 12 m3

- Weight one batch 1,000 kg

- Total electric power plant 230 kW.

- Drive power dryer drum 4 x 7.5 kW

- Area baghouse 430 m2

- power exhauster 55 kW

- tube height exhauster 15 meters

- Standard volume silo min. powder 15 m3

- Standard volume silage own dust 15 m3

- Performance bucket elevator 100 t / h

- Power bucket elevator 11 kW.

- mesh size sieve 5 mm, 12 mm, 22 mm, 35 mm.

- power vibration drive 2 x 3.2 kW

- Weighing hot inert materials 1,000 kg

- Power mixer drive 2 x 15 kW

- The dimensions of the cab 2.2 x 6 m

- The temperature of the final product 160 ℃

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call, hotline in Belarus

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: Republic of Belarus, 220073, Minsk, st. Olshevskogo, 20, office. 38a

e-mail: sales@zzbo.ru

Denis Zhilyakov

Director of the branch in the Republic of Belarus

Phone: +7 (951) 230-90-16

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions