Concrete plant LENTA-216

997 978 THE VILLAGE

859 259 THE VILLAGE

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Twin-shaft concrete mixer BP-2G-4500 (finished concrete 3 m³) |

| Overpass E4-216L |

| Storage hopper 3 m³ |

| Dosing block BD-180 (cement 1800 kg, water 1000 kg and chemical additive 50 kg) |

| Platform with ladders, for the installation of a DB and a storage bin |

| Dosing complex DKM-120 (4х30 m³) |

| Belt conveyor LK-1.0-30 |

| Control panel PA-3.0 SCADA-5.0 (120..216) with monoblock |

| ABAC Pole Position L20P Compressor (Italy) |

| Set for CBP assembly and connection |

| Двухвальный бетоносмеситель SICOMA MAO 4500 |

| operator Cab |

| Auger for cement ⌀32312000 |

| Cement silos to choose from |

| Binding for cement silos |

| Pump Calpeda MXH 202E |

| Water loading pump |

| Concrete Plant Insulation Kit |

| Thermal center for work in the winter season |

Automation system based on “SCADA” Based automation systemSiemens controller.

Software on its own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work.

CBP operation mode - fully automatic on the principle of "single button".

Twin-shaft concrete mixer BP-2G-4500 installed on a flyover, at a height of unloading the finished mixture of 4.2 meters. Concrete mixer volume for loading 4500 liters.

Concrete mixer equipped storage hopper with a volume of 3 m³ for preliminary storage of inert materials coming from the dosing complex.

Based automation system 2x55 kW. Based automation system 2.2 kW.

Concrete mixer equipped with automatic lubrication system.

ZZBO is the official dealer of SICOMA concrete mixers in Russia and the CIS!

It is possible to supply a concrete plant with a concrete mixer from the manufacturer SICOMA.

Dosing complex DKM-120 (4 x30) – предназначен для хранения и точного дозирования инертных.

Inert are loaded and stored in bunkers, number of bunkers 4 x 30 m³ each, total volume of bunkers 120 m³.

Под бункерами установлен ленточный конвейер-дозатор с шириной ленты 1000 мм и длиной 11 100 мм, на котором происходит точное дозирование компонентов, компоненты подаются из бункеров посредством открытия шиберных заслонок, заслонки управляются пневмосистемой. The number of dampers is 8 pieces. Suspended dosing conveyor on 4 strain gauges of 2 tons load capacity each. Dosing conveyor drive power 18.5 kW.

Dosing complex DKM-120 corrugated sheet with a thickness of 5 ... 6 mm.

Для побуждения схода песка, бункеры оборудованы вибраторами.

Suspended dosing conveyor 3 m³.

When the required dose of inert is collected, the DKM belt conveyor is turned on and the dosed components are fed to the main belt conveyor.

For maintenance of DKM-120 there is a platform with ladders.

Dosing complex DKM-120 length 30,000 mm. Chevron tape 1000 mm wide, tape thickness 10 mm, 4 layers.

Suspended dosing conveyor 30 kW. Drums 320 mm lined.

Equipped with a canopy from precipitation and a special ladder for maintenance.

The mixture rises along the conveyor and enters the storage hopper of the concrete mixer with a volume of 3 m³.

Storage hopper 3 m³. Wall thickness 5mm. Gate unloading control - pneumatic cylinder. A vibrator is installed to induce the exit. The inside of the bunker is covered armor 10 mm Hardox steel.

Based automation system consists of a cement dispenser for 1800 kg. The cement dispenser is equipped with 3 strain gauges of 1000 kg each and a vibrator to stimulate the cement flow.

The water dispenser for 1000 liters is equipped with 3 strain gauges of 1000 kg each.

Chemical dispenser additives per 50 liters on a 100 kg load cell.

Elevated structure serves as the installation of batchers, a storage hopper and a twin-shaft concrete mixer. It has two levels of service with ladders. Concrete unloading height 4 200 mm.

Based automation system для работы пневмосистемы завода с ресивером на 500 литров и производительностью 1210 л\мин.

Based automation system cement silos. The volume of silo for this plant is recommended from 100 tons. Silos for cement must be selected the rate of two daily stock performance. For feeding cement from a cement silo dispenser must acquire the correct length screw.

cement silos cement silos (recommended screw diameter 273 mm and length 15,000 m - not included in the basic equipment of the plant).

Cement silos, silo piping and augers are always in stock in Zlatoust!

One cycle lasts for 60 seconds maximum 3 m³ ready concrete or solution, the cycle lasts about 50…90 seconds. Plant capacity 100…216 m³ ready-made concrete or mortar per hour of work.

- Twin-shaft concrete mixer 4.5 cubic meters meters with belt feed, output 3 cu. meters

- Preliminary hopper for inert materials

- Dosing system (cement, water, chemicals) located on a separate platform

- Bunker 4 pieces of 30 cu. meters

- Installed in a place where concrete is needed, does not require foundation preparation SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work

- Transportation in 4 euro trucks to the installation site

- Full warranty 2 years

Technical Features

- Productivity, m³ hour 110...216

- Режим работы автоматический на ПО "SCADA"

- 31 095 $ 1

- Two-shaft concrete mixer BP-2G-4500 4500 liters for loading

- Hoppers (number x volume m³) 4 x 30

- Silo capacity (optional), tons 160...2060

- Load of inert materials into the concrete mixer belt conveyor

- Total power, kW 165

- Two-shaft concrete mixer BP-2G-750 700 (except for the warehouse of inert and technological areas)

- Weight, kg 58000

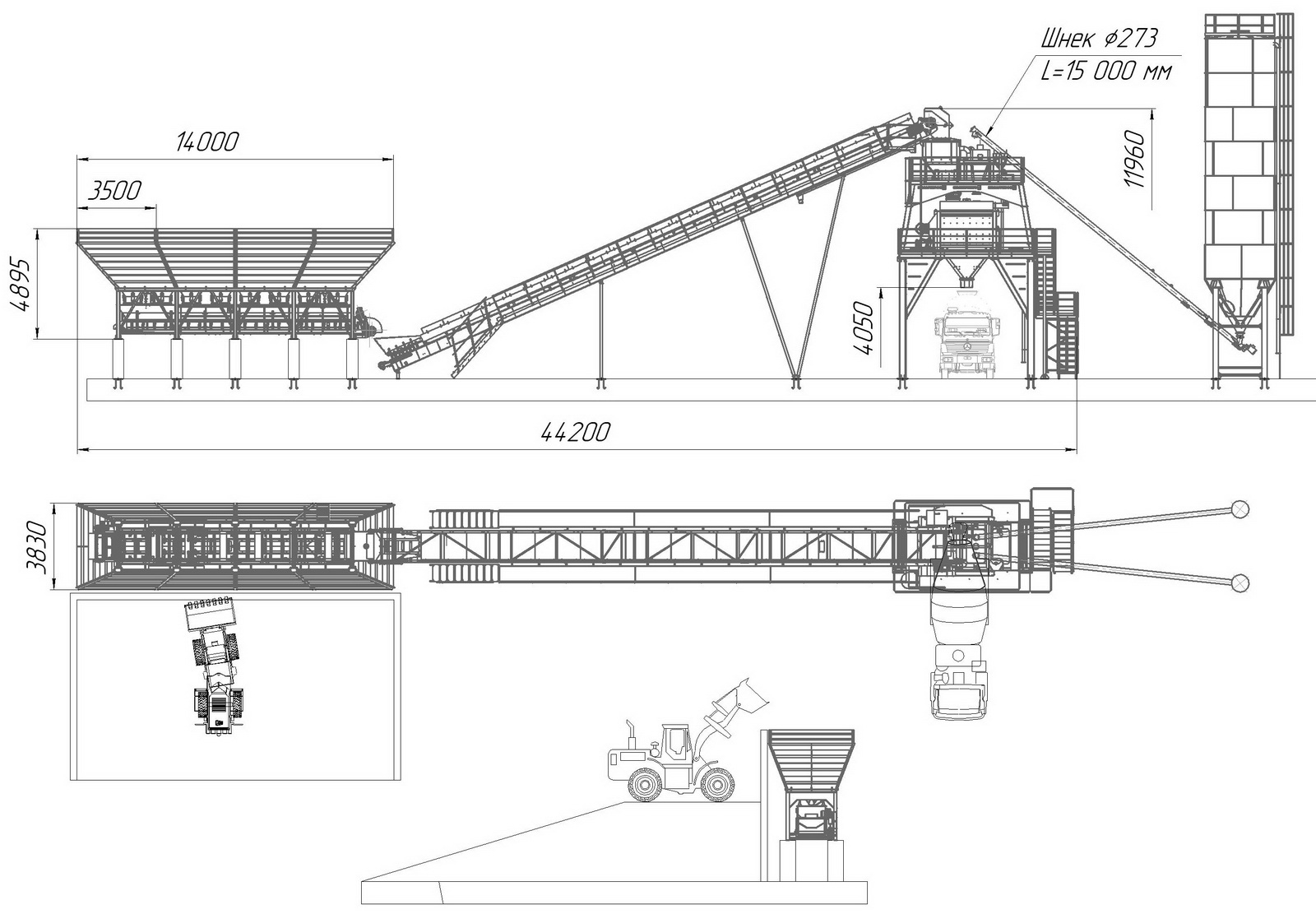

- Height, mm 11960

- Width, mm 3830

- Length, mm 44200

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call, hotline in Belarus

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: Republic of Belarus, 220073, Minsk, st. Olshevskogo, 20, office. 38a

e-mail: sales@zzbo.ru

Denis Zhilyakov

Director of the branch in the Republic of Belarus

Phone: +7 (951) 230-90-16

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions