Batching Complexes

Showing all 16 results

35 102 BYN

- The total volume of bunkers, the cube. m. 5

- The volume of the hopper, the cube. m. 2,5

- The number of bins, pieces. 2

- The maximum dose weighing kg up to 800

- Batching error,% ±1

- Belt speed, m c 1,3

- The pressure in the pneumatic system, MPa 0,6

38 351 BYN

- The total volume of bunkers, the cube. m. 10

- The volume of the hopper, the cube. m. 5

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1200

- Batching error,% ±1

- Belt speed, m c 1,3

- The pressure in the pneumatic system, MPa 0,6

69 324 BYN

55 556 BYN

- The total volume of bunkers, the cube. m. 12

- The number of bins, pieces. 2

- The volume of each bunker, cub. m. 84

- The maximum dose weighing kg up to 1000

- Batching error,% ±1

- Belt speed, m c 0,9

- The pressure in the pneumatic system, MPa 0,6...0,8

61 524 BYN

59 259 BYN

- The total volume of bunkers, the cube. m. 16

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1500

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

72 382 BYN

- The total volume of bunkers, the cube. m. 16

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1500

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

77 862 BYN

75 926 BYN

- The total volume of bunkers, the cube. m. 24

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 3

- The maximum dose weighing kg to 2000

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

91 600 BYN

- The total volume of bunkers, the cube. m. 24

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 3

- The maximum dose weighing kg to 2000

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

107 431 BYN

- Total volume of bunkers, m³ 32

- Volume of one bunker, m³ 8

- The number of bins, pieces. 4

- Мощность привода ленточного конвейера, кВт 11

- The width of the conveyor belt, mm 800

- Угол наклона конвейера, ° 4,5

- Скорость движения ленты, м/с 1,3

100 351 BYN

- Total volume of bunkers, m³ 32

- Volume of one bunker, m³ 8

- The number of bins, pieces. 4

- The maximum dose weighing kg 14 910 $

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

184 142 BYN

- Vibrator power, kW 5

- Vibrator power, kW 8

- Vibrator power, kW 2,2

- Vibrator power, kW 500

- Maximum productivity of the belt feeder, t/h Operating thermal power of the burner, MW

- Maximum productivity of the belt feeder, t/h 0Vibrator power, kW

- Maximum productivity of the belt feeder, t/h 7.5

88 240 BYN

- Total volume of bunkers, m³ 40

- Volume of one bunker, m³ 20

- Vibrator power, kW 2

- The maximum dose weighing kg 14 910 $

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

110 764 BYN

- The total volume of bunkers, the cube. m. 60

- The volume of the hopper, the cube. m. 20

- The number of bins, pieces. 3

- The maximum dose weighing kg до 4500

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

146 567 BYN

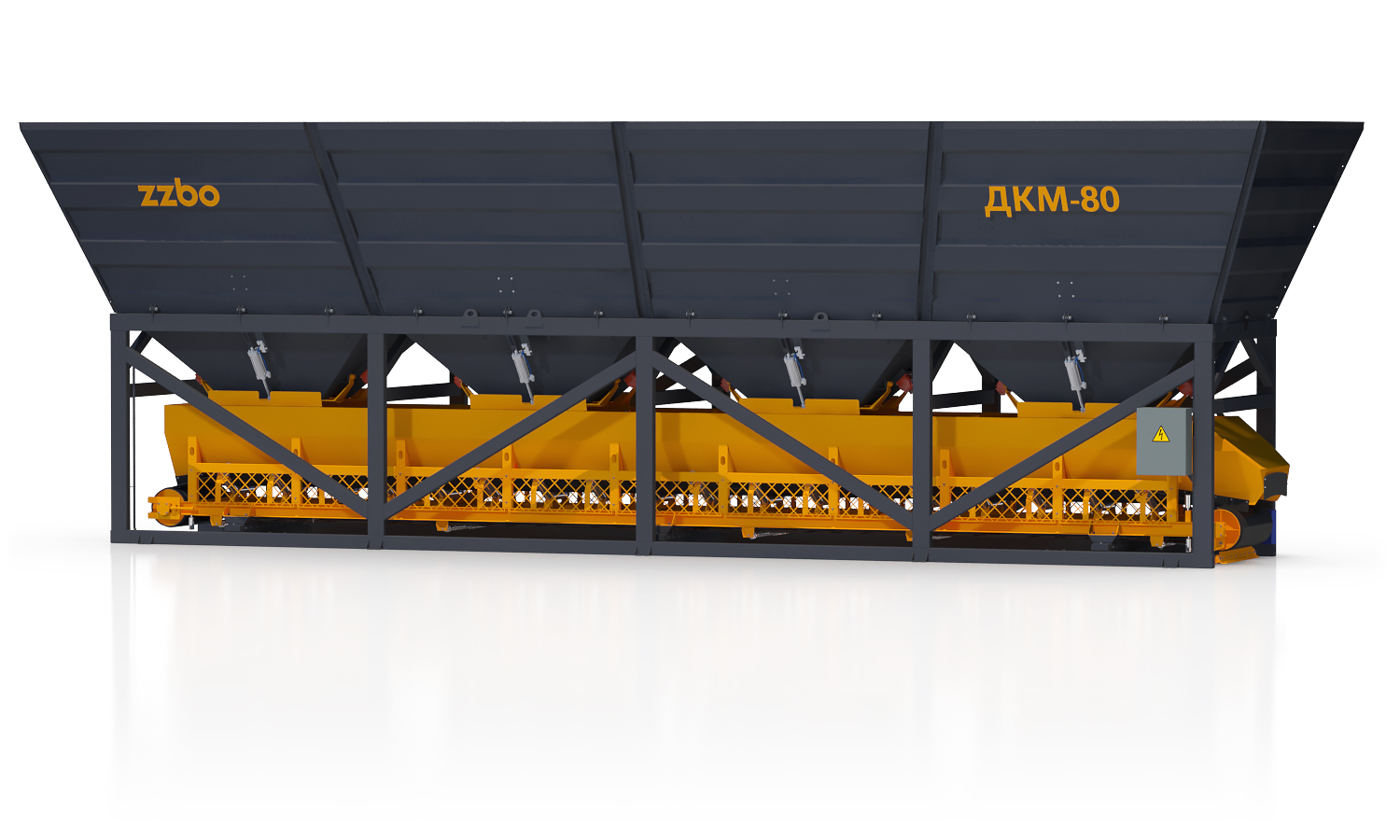

- Total volume of bunkers, m³ 80

- Volume of one bunker, m³ 20

- Vibrator power, kW 4

- The maximum dose weighing kg 6000

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

183 071 BYN

155 556 BYN

- Total volume of bunkers, m³ 120

- Volume of one bunker, m³ 30

- Vibrator power, kW 4

- Batching error,% ±1

- Скорость движения ленты, м/с 1,4

- The pressure in the pneumatic system, MPa 0,6...0,8

- Aggregate size, mm max 70

Dosing complexes concrete plants ZZBO

Performance of a concrete plant and the quality of its products - branded concrete mix - depends not only on the technical characteristics of the mixer, and the exact dosage of concrete components, as well as the feed rate into the mixer for further mixing.

Purpose metering systems

В число компонентов бетона входят так называемые инертные заполнители – песок, гравий, щебень, песчано-гравийная смесь, керамзит, отсев и другие насыпные материалы. Для хранения инертных материалов (далее – ИМ) отводятся значительные территории, поскольку их нередко поставляют целыми эшелонами. Обычно ИМ складируют под открытым небом, в лучшем случае – под навесом. Естественно, что на рабочей площадке БСУ необходимо обустраивать специальные участки, на которых бы определенные объемы песка, щебня и других ИМ, задействованных в техпроцессе, временно складировались и уже с этих участков напрямую «включались» в технологическую цепочку. На современных бетонных заводах этим целям служат дозирующие комплексы (далее – ДК) бункерного типа, выполняющие следующие функции:

- Temporary accumulation and storage of a small stock of MI, ensuring continuity of production.

- Defrosting, drying and MI heating in autumn and winter with year-round operation.

- The weight IM dosing according to the selected recipe of the concrete mix.

The composition and operation of the DC production ZZBO

Dosing ZZBO complexes consist of the following elements:

- bins volume from 5 to 12 and a cube. meters for the storage of inert materials;

- supporting frame for placing and fixing elements DK;

- dispenser inert conveyor type;

- sector gate opening hoppers bins;

- пневмооборудования;

- вибраторов-встряхивателей);

- стальных тензодатчиков S-образного типа;

- пульта управления ДК в полуавтоматическом режиме, когда оператор нажатиями соответствующих кнопок управляет открываниями затворов бункеров и контролирует по соответствующему табло процесс дозировки. В настоящее время ZZBO может поставлять ДК с автоматическим пультом управления для работы ДК в автоматическом режиме.

In preparation for the winter season hopper equipped with DC registers liner steam from the steam generator or air ducts for hot air from the heat source.

Загрузку ИМ со стационарных складов осуществляют ковшовым погрузчиком. Каждый тип сырья отгружается только в свой бункер. Смешивание в бункере двух типов сырья не допускается.

Feeder-conveyor is suspended on the 4-S-type load cells, which provides a more accurate indication of parameters in comparison with the Chinese outdoor counterparts.

Work dosing process takes place in the following sequence:

- On operator command (or the remote automatic control), inert fillers of each bin in accordance with the prescription in doses received through the output gates to a tape dispenser, conveyor.

- Feed each of them to produce portions while weighing.

- With the accumulation of the required weight on the belt conveyor moves all the components of aggregates in the bucket or skip to the tape feed ingredients in the mixer.

- Further, the duty cycle is repeated a number of times.